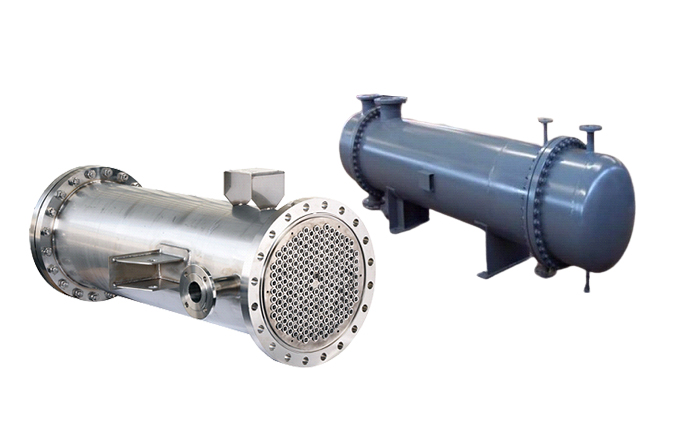

UMA CHEM PHARMA MACHINERIES design and manufacturers Heat Exchanger and Columns. The flow in Heat Exchanger transfer coefficients with minimum increase in pressure drop. This are used as vapour condenser, effluent cooler, exhaust gas cooler etc. In chemical, pharmaceutical, fertilizer, cement, biotechnology, power generation, food, drink, brewing, environmental processes

Heat Exchangers are fabricated in Hastealloy, Inconel, all grade of Stainless Steel & Carbon Steel & any other weldable material operating in moderately high pressure and temperature range.

For Details

I'll get back to you as quickly as possible